PROJECTS

R&D Consortium MATICS 2023-2026

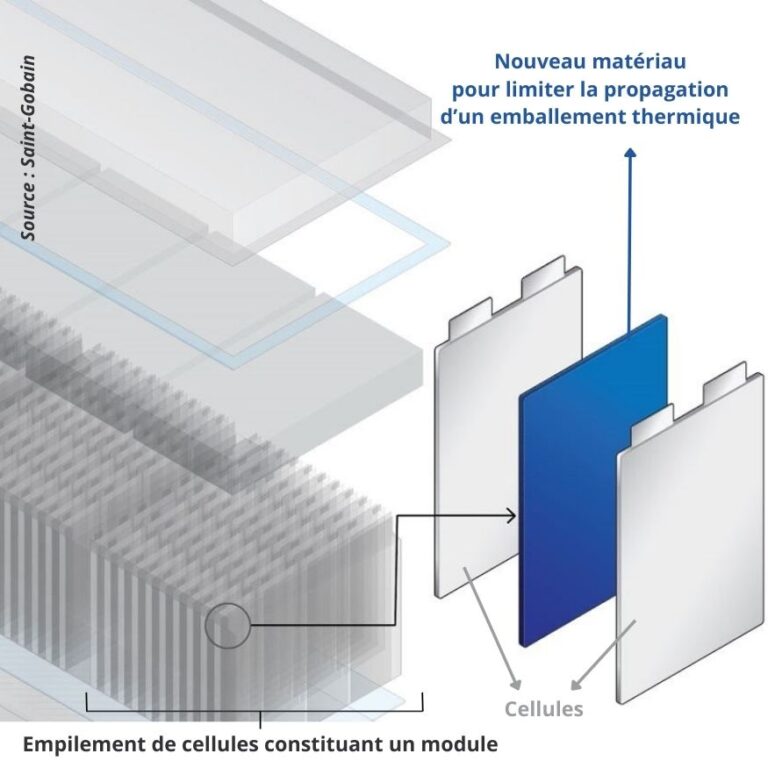

Next-gen battery module with advanced thermal shielding

The goal of the MATICS project is to develop, evaluate, and simulate safe battery modules equipped with thin thermal barriers to prevent cell-to-cell thermal runaway propagation.

The consortium brings together partners with complementary expertise: Saint-Gobain Research Paris, Verkor, Enersens, and LEMTA, to jointly address the project’s key challenges:

- Measurement, characterization, and modeling

- Development of multifunctional thin materials

- Design of pouch cell battery modules

Ce projet a été financé par l’État dans le cadre de France 2030

Financé par l’Union européenne – Next Generation EU dans le cadre du plan France Relance

EN.MOTION 2022-2025

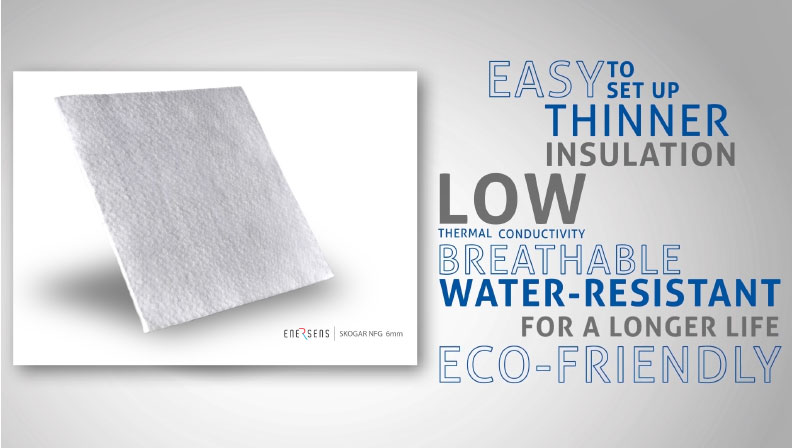

Innovative Manufacturing Process for Super-Thin Thermal Barriers

The objective of the EN.MOTION project is to develop an innovative process to manufacture efficiently our range of thin thermal barriers Skogar.

This project is funded through the EIC Accelerator program of the European Union.

This innovative process is built on top of our world-class IP and is efficient in all regards:

- Economically and Environmentally, using tailor-made equipment to reduce energy consumption, labour, and optimize raw materials utilization;

- From a product quality standpoint, as our proprietary equipment has been designed to manufacture high quality blankets, with top-of-the-line characteristics (thermal conductivity, fire behaviour, mechanical properties, etc).

AEROTEX 2020, September – 2022, August

Towards more efficient thermal insulation solutions for sports, buildings and personal protective equipment

The AEROTEX project, certified by the competitiveness cluster dedicated to the French textile industry Techtera, is supported by the Auvergne-Rhône-Alpes region as part of the R&D Booster program. It concerns the development of new industrial manufacturing processes for flexible high performance textile materials.

The AEROTEX project, led by the FIBROLINE company, brings together 6 industrial partners and laboratories working hand in hand to develop new industrial manufacturing processes for high performance flexible textile materials for three important application markets: personal protective equipment , outdoor sports, and construction.

The companies MILLET MOUNTAIN Group -with the brands Millet and Lafuma- (sport), BALSAN (EPI) and P.E.G. (Building) are collaborating with technology suppliers such as ENERSENS (innovative insulating materials based on airgel), FIBROLINE (innovative eco-sustainable processes: dry impregnation technology) and CETHIL UMR5008 (CNRS, INSA-LYON, Univ . Lyon1), a laboratory energy and thermal. The products developed should bring real progress in the field of insulation, in markets which require both advanced technicality and materials highly adapted to use, with increased conformability, lightness, durability. comfort, and ease of use.

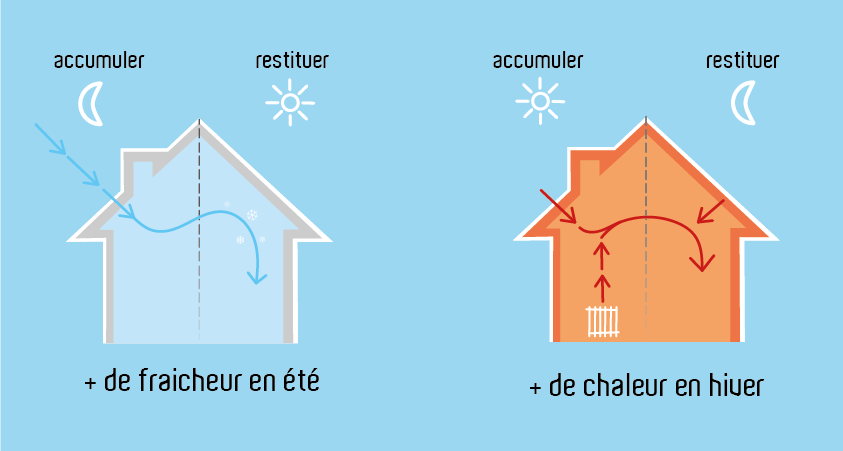

MATIBAT 2018, June – 2021, May

Materials for thermal inertia in buildings

The field of reducing energy consumption for buildings represents a research theme and active innovation, and is part of the necessary evolutions, initiated by the Kyoto Protocol and the Grenelle of the environment. But the feedback shows that the technical solutions used to date in building projects, in renovation as in construction are not adapted to the attainment of ambitious targets of energy performance and especially the conditions of summer comfort once in operation.

The aim of the project is therefore to develop «inertial» solutions to perform the two main functions:

- Delay the heat front at the roof, and possibly the exposed facades (usually West) by integrating inertia to the constructive elements providing thermal insulation,

- Cushion increases in indoor temperature by integrating high thermal inertia with high effusivity and low diffusivity into the living spaces of buildings.

These two points will ensure optimal summer comfort and will thus significantly reduce energy consumption, for example for air conditioning.

Ce projet a été financé par la Région Auvergne-Rhône-Alpes dans le cadre des appels à projet FUI 24.

WALL-ACE 2016, October – 2019, September

Wall Insulation Novel Nanomaterials Efficient Systems

The objective of the Wall-ACE project is to develop an innovative set of new insulation products and systems sustainable and advanced. The “HONEST” solution (high performance systems optimized for efficiency energy through nanotechnology) is a modular toolkit, providing a set of solutions to meet most of the challenges of thermal renovation and construction new.

The HONEST solution includes: Low Emissivity Thermal Insulation Coating, High Performance Indoor Insulation Plaster, High Performance Indoor Insulation Coating, High Performance Outdoor Insulation Coating and Terracotta Insulation Bricks. These products, composed mainly of mineral materials, guarantee a low environmental impact, a perfect safety at installation, a non degradation of the air quality while keeping all the qualities of performance, fire resistance, humidity and parasites.

These high-performance products will be achieved through synergy between the different consortium members by combining high-performance and sustainable nanotechnology, which is silica aerogel, with existing products already approved. The properties and production costs of the products will be optimized throughout the project, in order to achieve the best possible value for money. It will also be a question of carrying out a scale-up of industrial processes in order to be able to reach a large volume of products and to distribute throughout Europe all of our innovations. The project also focuses on the Go To Market of these five products. For this purpose, market studies and field tests will be carried out, so that evaluations of the performance of our products are validated in real conditions to obtain the certifications required by the building.

The objective is a rapid introduction of our products to the market. The innovations of the Wall-ACE project are key elements in saving energy and significantly reducing CO2 emissions at European level. They will strengthen Europe’s industrial leadership and competitiveness in the global construction sector.

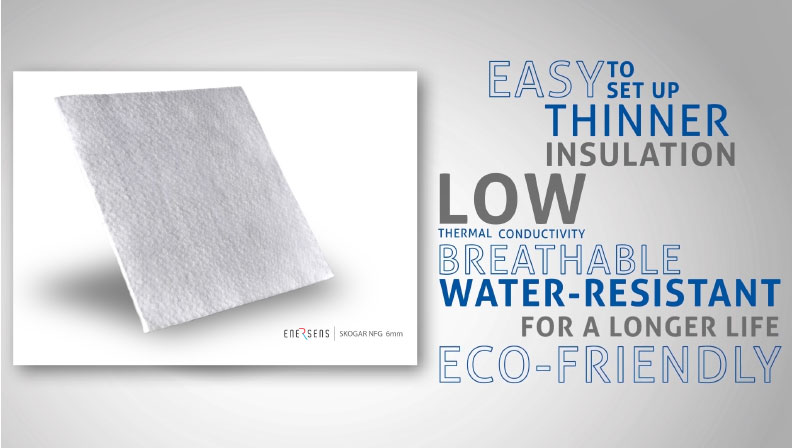

HOMESKIN 2015, February – 2018, January

Thinner Insulation Systems

Piloted by ENERSENS, the Homeskin project associates experimented partners and very enthusiastic from renowned univerities to isolation system specialist. It fits perfectly to the roadmap of ENERSENS and with the program of the Key Enabling Technologies (Keys Technologies) of the European Union and contribute to accelerate the development of super-insulation in Europe.

The Homeskin project set up by ENERSENS et his partners has an overall budget envelope of 6.3M€ and receives funding Horizon 2020, the research and innovation program of European Union, at the end of the financing agreement n°636709, for an amount of 4.5 M€. The purpose of developing insulation systems for exterior and interior facades, walls and roofs, while optimizing the manufacturing techniques of this type of material. In addition, Homeskin makes valuable contributions to standards and regulations for very high performance insulation.

Homeskin helps bring revolutionary technology to market with the following benefits:

- Reduction of at least 30% of grey energy (used for manufacturing) and CO2 emissions at the component level;

- Improvement of at least 20% of insulation properties;

- Minimum 15% reduction in total costs compared to existing equivalent solutions;

- A reduction of at least 5% of the energy consumed during the entire life cycle of a building.

PAREX.IT 2015, February – 2018, January

External thermal insulation composite systems

An innovative solution of insulation from the outside comes in the form of a coating projected on the main body, incorporating silica aerogel granules, which are used using conventional tools.

Insulation from the outside is a growing market, driven by thermal renovation. In 2013, the French market is now close to 20 million square metres per year, nearly double the figures for 2010. The Parex.IT (“Exterior Siding for Thermal Insulation”) project is a collaborative project that aims to develop a projectible mineral insulating coating, consisting of an adjuvanted hydraulic matrix with silica aerogel insulating granules.

An innovative product that provides continuous insulation, unlike cutting plates, and whose performance is high: the coefficient of thermal conductivity was measured at 0.027 W/m.K (against 0.034 for rock wool and 0.036 for polystyrene). Stéphane Le Fay, Project Manager for Parex Group, explains: After several months of development, the plaster formulation obtained by the project stakeholders has very convincing results, both in terms of implementation, fire resistance, moisture permeability, and above all the thermal performance (…) which is much higher than that of expanded polystyrene, which is much more difficult to apply than the coating.”

AEROCOINS 2011, June – 2015, June

Aerogel-Based Composite/Hybrid Nanomaterials for Cost-Effective Building Super-Insulation Systems

In the context of global climate control policies, improving the energy efficiency of existing buildings is a major challenge, both globally and at the European level. The reduction in the energy consumption of buildings is now preferably achieved by increasing the resistance thermal insulation layer in the building envelope.

The AEROCOINS project has contributed significantly to the future reduction of energy consumption by reducing the heating and cooling requirements of existing buildings. An intelligent combination of soil-gel science and nanotechnology has greatly advanced the design and development of new super-insulating aerogels. The AEROCOINS project has created a new class of super-composite/hybrid materialsinsulation by overcoming the two main long-standing obstacles that have prevented the wider use of these silica aerogel materials in the building industry.

They were reinforced by cross-linking with cellulosic polymers or by the incorporation of cellulose-based nanofibres. The production cost of these aerogel composite plates has been reduced through a process of drying in the ambient and by the development of continuous production technology.

SIPA BAT 2010, January – 2014, July

Super Atmospheric Pressure Insulation for the Building

The aim of SIPA-BAT was to develop quilted and super thick insulating panels. The success was there since several products and synthetic pathways were patented. Thus panels and quilted three times more insulating than rock wool (or three times thinner for the same insulation) intended primarily for the thermal renovation of buildings were developed.

These non harmful products in case of fire will achieve the thermal performance of Low Consumption Buildings with any type of constructive mode.